Lintlha

Ts'ebeliso ea mantlha ea tšepe e sa sebetseng kantle ho naha:

1) Mechini ea kaho le lisebelisoa: poleiti ea bakete ea li-bulldozer excavator, poleiti ea lehlakore, poleiti e tlase ea bakete, lehare, poleiti.

2) Mechini le lisebelisoa tsa ho laolla le ho laolla: poleiti ea leloala ea ho theola, poleiti ea ho roala, poleiti ea blade, poleiti ea boholo bo mahareng ea ho lahlela teraka.

3) Mechini ea kaho le lisebelisoa: poleiti ea meno ea samente, poleiti ea motsoako oa konkreite, poleiti e kopanyang ea fatše, poleiti e bokellang lerole.

4) Mechini le lisebelisoa tsa tšepe: tšepe ea tšepe e fetisang setsoe, mochini oa tšepe oa tšepe oa tšepe, poleiti ea mochini oa scraper.

5) Mechini ea merafo le lisebelisoa: poleiti ea lera ea mochini oa merafo.

6) Lisebelisoa tse ling tsa mochini: moqomo oa lehlabathe, lehare, likarolo tse fapaneng tse sa sebetseng tsa mochini oa boema-kepe.

7) Thepa ea motlakase e futhumatsang mocheso: boto ea leloala la mashala, scutcher ea mashala, phala ea phepelo ea mashala, poleiti ea phepelo ea mashala, boto ea thepa ea ho laolla mashala.

8) Lisebelisoa tsa mochini tse thunyang: poleiti ea mochini oa mochini o thunyang

Ho tloha ha e thehoa, k'hamphani e bile boleng ba lihlahisoa e le bophelo ba mantlha ba khoebo, boleng ba tšebeletso e le borokho ba katleho ea rona, re tšepa ka tieo ho theha likamano tsa khoebo le bareki ba rona, ho fana ka litšebeletso tsa boleng, ka khoebo, ntshetsopele e tshwanang.

Ka ntlafatso e tsoelang pele, boqapi, e le hore boemo ba boleng ba lihlahisoa tsa rona bo lule bo le ka pele ho indasteri ea lapeng.

Sepheo sa boleng: 98% ea lihlahisoa li feta tlhahlobo ea pele ea ho fana, 0.2% ea lihlahisoa tse ka holimo li feta keketseho ea pele ea tlhahlobo ea selemo le selemo, 100% ea lihlahisoa li feta fekthering.

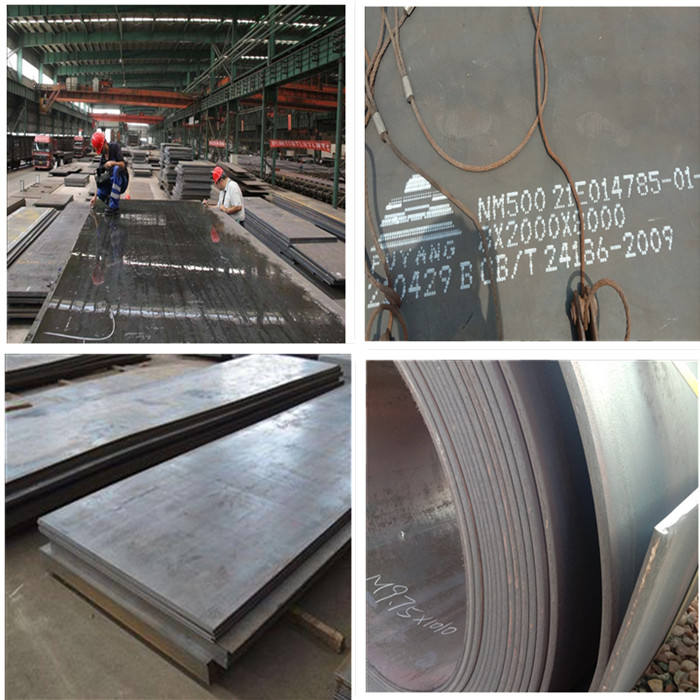

"Botšepehi, ho batla 'nete, ntshetsopele, popontshwa" ke morero oa khoebo oa k'hamphani ea rona ka lilemo tse ngata, amohela ka mofuthu basebelisi ba bangata ba tšepe e sa hloekang le basebetsi-'moho le bona ho etela k'hamphani ea rona, ka lebaka la ho roala poleiti ho theha botle bo khanyang.

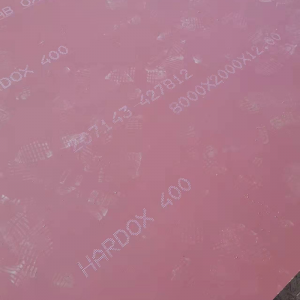

Letlapa la tšepe le hlolehang ho roala

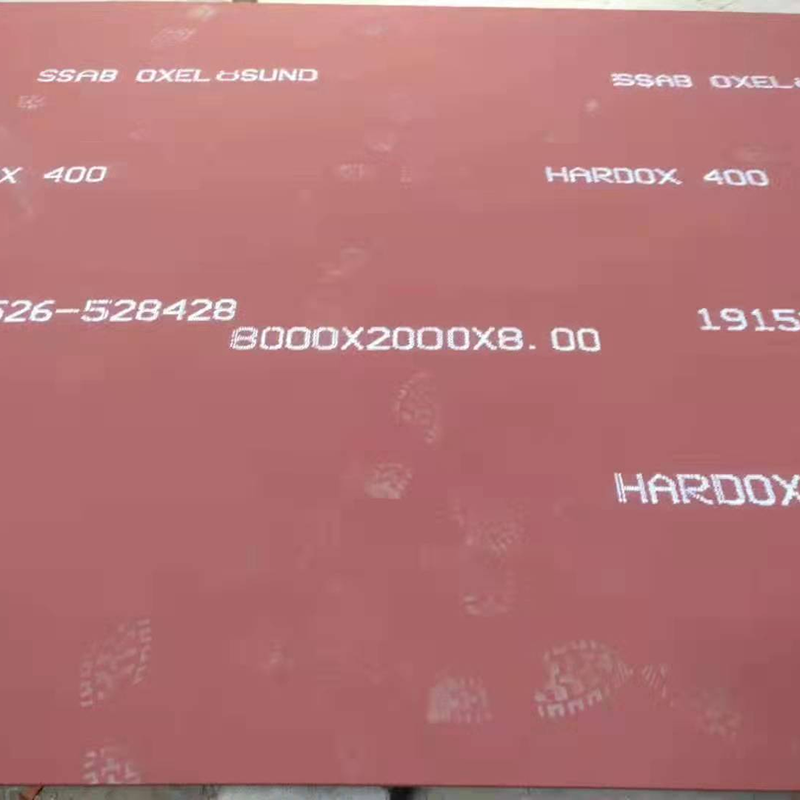

| Kereiti | NM360/NM400/NM450/NM500/RAEX400/RAEX450/RAEX500/NM360,BHNM400,BHNM450,BHNM500,BHNM550,BHNM600,BHNM650,NR43060,NR4360,NR4360,NR4360,NR4360,NR4060,NR450 |

| Botenya | 3+3,4+4,5+5,6+4,6+5,6+6,8+4,8+5,8+6,8+7,8+8,10+4,10+ 5,10+6,10+7,10+8,10+9,10+10,10+20,12+4,12+5,12+6,12+7,12+8,12+9, 12+1,12+11,12+12, 12+17,14+6,14+8,14+10,16+6,16+8,16+10,18+6,18+8,18+10,20+5,20+6,20+ 8,20+10,20+20,30+10,40+10, e hlophisitsoeng |

| Bophara | 1500/2000/2500/3000MM |

Lihlahisoa tse ling

1. E babatsehang ho apara ho hanyetsaMotsoako oa lik'hemik'hale oa lesela le sa sebetseng la alloy le na le khabone ea 4 ho 5% le chromium ea 25 ho isa ho 30%.Karolo ea molumo oa Cr7C3 carbides mohahong oa metallographic e feta 50%.Ho thatafala ha macroscopic ke HRC56 ho isa ho 62. Ho thatafala ke HV1400~1800. Hobane carbides li ajoa perpendicularly ka tataiso ea ho apara, esita le ha li bapisoa le li-alloys tse entsoeng ka mokhoa o tšoanang le boima, ho hanyetsa ho apara ho feta habeli.Papiso le ho hanyetsa ho apara ha lisebelisoa tse 'maloa tse tloaelehileng ke tse latelang: (1) Ka tšepe e tlaase ea carbon;20~25:1 (2) Ka tšepe ea as-cast e phahameng ea chromium;1.5~2.5:1

2. Tšusumetso e ntle ea ho hanyetsaBotlaaseng ba poleiti ea tšepe e sa sebetsaneng le ho roala ke tšepe e tlase ea khabone kapa alloy e tlase.Lisebelisoa tse thata tse kang tšepe e sa hloekang li bontša bophahamo ba bimetal.Lera le sa tsitsang le hanana le ho roala ha mokhoa oa ho roala, 'me substrate e jara moroalo oa bohareng, kahoo e na le ts'ebetso e ntle ea ho hanyetsa.E khona ho mamella tšusumetso le ho roala ha "hopper" e phahameng ka har'a sistimi e tsamaisang thepa.

3. Ho hanyetsa mocheso o motleThe alloy wear-resistant layer e khothalletsoa hore e sebelisoe tlas'a ≤600 ℃.Haeba vanadium, molybdenum le li-alloys tse ling li kenyelletsoa lera le sa tsitsang la alloy, le ka mamella ho roala ha mocheso o phahameng oa ≤800℃.Mocheso o khothalletsoang oa ho sebetsa ke o latelang: Letlapa le tloaelehileng la carbon steel base le khothalletsoa hore le sebelisoe tlas'a boemo ba ho sebetsa bo sa feteng 380 ℃;Litšepe tsa tšepe tse sa keneleng mocheso o tlase (15CrMo, 12Cr1MOV, joalo-joalo) li khothaletsoa hore li sebelisoe maemong a ts'ebetso a sa feteng 540 ℃;Karolo e ka tlase ea tšepe e sa keneleng mocheso e khothaletsoa hore e sebelisoe ka mochesong o sa feteng 800 ° C.

4. Ho hanyetsa ho hotle ha kutuLera la alloy la poleiti ea tšepe e sa sebetseng e manganga e na le liperesente tse phahameng tsa tšepe ea chromium, ka hona e na le tekanyo e itseng ea mafome le ho hanyetsa ho bola.E ka sebelisoa ho thibela mashala ho khomarela ha e sebelisoa meqomong le li-hoppers tsa mashala.

5. Mefuta e felletseng le litlhalosoLetlapa la tšepe le sa sebetseng le na le litlhaloso tse felletseng le mefuta e mengata, 'me e se e le serialization ea khoebo.Botenya ba lera la alloy le sa sebetseng ke 3-20mm.Botenya ba poleiti ea tšepe e kopantsoeng ke bonyane 6mm, 'me botenya ha bo felle.Letlapa le tloaelehileng la tšepe le sa sebetseng le ka fanoa ka 1200 kapa 3800 × 12000mm, hape le ka sebetsoa ho latela boholo ba litšoantšo ho latela litlhoko tsa mosebelisi.Lipoleiti tsa tšepe tse sa khoneng ho apara li se li arotsoe ka mefuta e meraro: mofuta o tloaelehileng, mofuta o hananang le tšusumetso le mofuta o phahameng oa mocheso.Ho odara lipoleiti tsa tšepe tse kopantsoeng tse nang le mocheso o phahameng oa mocheso o phahameng le tse hananang le tšusumetso ho lokela ho hlalosoa.

6. Ts'ebetso e bonolo ea ts'ebetsoLetlapa la tšepe le manganga le ka sehoa, la kobeha kapa la kobeha, la chesoa le ho phunngoa, 'me le ka sebetsoa ka likarolo tse fapaneng tse ka sebetsoang ka lipoleiti tse tloaelehileng tsa tšepe.Lipoleiti tsa tšepe tse sehiloeng tse manganga li ka tjhesetsoa ka mokhoa o itseng ka likarolo tse fapaneng tsa sebopeho sa boenjiniere kapa likarolo.

7. Mesebetsi le LikaroloE ka chesetsoa 'me e na le khanyetso e ntle ea ho apara..